Scientific Name

Calophyllum kajewskii

Trade Name

Calophyllum

Family Name

Guttiferae

Common Names

Ba’ula, Buni, Buni buni, Buni soloso, Bush calophyllum, Calophyllum, Damanu, Fteh, Island cedar, Ka thang han, Ka thang lan, Kalofilum, Kioli, Koila, Koilo, Kokilo, Legitu, Pagura bunu, Penaga, Poon, Rakich, Solomon Islands calophyllum, Tamanou, Tang hon, Ureure, Wangu

Regions of Distribution

Oceania and S.E. Asia

Countries of Distribution [VIEW MAP]

Australia, Fiji [Polynesia], Fiji, India, Indonesia, New Caledonia, Papua New Guinea, Philippines, Solomon Islands, Thailand

Common Uses

Balusters, Bedroom suites, Blockboard, Boat building (general), Boat building, Boat building: decking, Boxes and crates, Bridge construction, Building construction, Building materials, Cabinetmaking, Canoes, Casks, Chairs, Chests, Coffins, Concealed parts (Furniture), Construction, Cutting surfaces, Desks, Dining-room furniture, Domestic flooring, Dowell pins, Dowells, Drawer sides, Drum sticks, Excelsior, Factory flooring, Fine furniture, Floor lamps, Flooring, Furniture , Furniture components, Furniture, Hardboards, Interior trim, Joinery, Light construction, Matches, Moldings, Musical instruments , Musical instruments, Musical instruments: piano, Novelties, Paneling, Particleboard, Piling, Plywood, Poles, Pulp/Paper products, Pulpwood, Shipbuilding, Tables, Toys, Turnery, Vehicle parts, Veneer, Veneer: decorative

Environmental Profile

| Abundant/Secure | ||||||||||||

| Status unknown due to inadequate information | ||||||||||||

| Status has not been officially assessed |

Distribution Overview

Throughout Southeast Asia, on different growing sites, from coastal and swamp to mountain forests

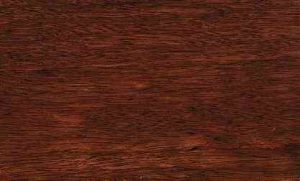

Heartwood Color

| Pink | ||||||||||||

| Green/grey | ||||||||||||

| Red | ||||||||||||

| Brown | ||||||||||||

| Reddish brown | ||||||||||||

| Pale red to pink | ||||||||||||

| Pale brown |

Sapwood Color

| Brown | ||||||||||||

| Different than heartwood | ||||||||||||

| Clearly differentiated from the heartwood | ||||||||||||

| Pale brown | ||||||||||||

| Orangish |

Grain

| Figure | ||||||||||||

| Interlocked | ||||||||||||

| Even | ||||||||||||

| Straight | ||||||||||||

| Stripe (figure) | ||||||||||||

| Rippled (figure) | ||||||||||||

| Zig Zag |

| Interlocked | ||||||||||||

| Striped figure | ||||||||||||

| Straight | ||||||||||||

| Rippled figure | ||||||||||||

| Figure is sometimes in a zig zag pattern |

Quartersawn stock has a ribbon figure and flatsawn stock sometimes has a zig zag pattern.

Texture

| Fine | ||||||||||||

| Very fine | ||||||||||||

| Even or uniform | ||||||||||||

| Uniform | ||||||||||||

| Medium coarse to coarse | ||||||||||||

| Uneven textured | ||||||||||||

| Medium | ||||||||||||

| Coarse |

Luster

| Low | ||||||||||||

| Medium | ||||||||||||

| Lustrous |

Natural Growth Defects

| Mostly knot free |

Trees that are overmature may have white pocket rot

Natural Durability

| Non-durable | ||||||||||||

| Perishable | ||||||||||||

| Susceptible to insect attack | ||||||||||||

| Non-resistant to marine borers | ||||||||||||

| Non-resistant to termites | ||||||||||||

| Resistant to powder post beetles | ||||||||||||

| Non-resistant to termites | ||||||||||||

| Moderately durable | ||||||||||||

| Resistant to attack from powder post (Lyctid & Bostrychid) beetles | ||||||||||||

| Susceptible to attack from termites (Isoptera) | ||||||||||||

| Resistant to wood staining fungal attack | ||||||||||||

| Susceptible to pin-hole borer, termite and marine borer attack | ||||||||||||

| Susceptible to marine borer attack | ||||||||||||

| Resistant to attack from pinworms (ambrosia beetles) | ||||||||||||

| Pinworms (ambrosia beetles) are commonly present | ||||||||||||

| May stain under damp conditions | ||||||||||||

| Durable above ground |

Odor

| No specific smell or taste |

Silica Content

| Siliceous |

Light-Induced Color Change

| Darker |

Toxicity

| Some toxic effects |

Kiln Schedules

| Kiln Drying Rate (in days) is rapid | ||||||||||||

| T2 – D4 (4/4); T2 – D3 (8/4) US | ||||||||||||

| Schedule A (4/4) United Kingdom |

Drying Defects

| Distortion | ||||||||||||

| Discoloration | ||||||||||||

| Splitting | ||||||||||||

| Moderate twist/warp | ||||||||||||

| Moderate surface checking |

Ease of Drying

| Fairly Easy | ||||||||||||

| Rapidly | ||||||||||||

| Thick Stock Requires Care | ||||||||||||

| Reconditioning Treatement | ||||||||||||

| Little degrade | ||||||||||||

| Requires special attention | ||||||||||||

| Thinner boards (<1″) dry easily | ||||||||||||

| Special attention required | ||||||||||||

| Easy |

Properly stack material. A 4 to 5 hour steaming treatment with stack weighted down can reduce twist and stresses

Kiln Drying Rate

| Naturally dries quickly | ||||||||||||

| Rapid (<10 days for boards < 32 mm, to <30 days for boards >= 63 mm) |

Tree Identification

| Bole/stem form is straight | ||||||||||||

| Bole/stem form is not buttressed |

Tree Size

| Tree height is 30-40 m | ||||||||||||

| Tree height is 20-30 m | ||||||||||||

| Trunk diameter is 100-150 cm |

Stems are straight and cylindrical, and are usually clear of branches to 40 to 60 feet (12 to 18 m). Often described as fast-growing.

Blunting Effect

| Little | ||||||||||||

| Medium effect |

Interlocked grain causes a medium blunting effect on cutting tools

Boring

| Fairly easy to very easy | ||||||||||||

| Easy |

Cutting Resistance

| Easy to saw | ||||||||||||

| Fairly Difficult to Very Difficult to saw | ||||||||||||

| Cutting Resistance with green wood is easy | ||||||||||||

| Cutting Resistance with dry wood is easy | ||||||||||||

| Material with interlocked grain can be difficult. |

Gluing

| Easy to glue | ||||||||||||

| Very good properties |

Movement in Service

| Stable | ||||||||||||

| Small | ||||||||||||

| Medium | ||||||||||||

| High |

Nailing

| Very Good to Excellent Results | ||||||||||||

| Fair to Good Results | ||||||||||||

| Easy to nail | ||||||||||||

| Holds nails well |

Planing

| Poor to Very Poor Results | ||||||||||||

| Fairly Easy to Very Easy | ||||||||||||

| Fair to Good Results | ||||||||||||

| Moderately easy to plane | ||||||||||||

| Good planing properties | ||||||||||||

| Difficult to plane |

Grain may tear if interlocked. Recommended that a reduced cutting edge is used

Resistance to Impregnation

| Permeable heartwood | ||||||||||||

| Permeable sapwood | ||||||||||||

| Resistant heartwood | ||||||||||||

| Resistant sapwood | ||||||||||||

| Heartwood is resistant | ||||||||||||

| Heartwood is extremely resistant |

Heartwood extremely resistant to pressure treatment

Response to Hand Tools

| Easy to machine | ||||||||||||

| Good response |

Sanding

| Poor sanding qualities | ||||||||||||

| Moderate sanding qualities |

Cross-Grain can make sanding qualities poor

Screwing

| Screwing yields good results | ||||||||||||

| Good screw holding properties | ||||||||||||

| Easy to screw |

Turning

| Poor to Very Poor Results | ||||||||||||

| Fairly Easy to Very Easy | ||||||||||||

| Satisfactory turning properties | ||||||||||||

| Good results |

Turned surfaces tend to be woolly

Veneering Qualities

| Veneers easily | ||||||||||||

| Veneers moderately easy | ||||||||||||

| Suitable for peeling | ||||||||||||

| Good gluing qualities | ||||||||||||

| Easy to cut | ||||||||||||

| Drying degrade is often moderate to severe, with collapse, buckles, and splilts |

Painting

| Satisfactory results |

Polishing

| Good results | ||||||||||||

| Smooth polished surface | ||||||||||||

| Requires a filler |

Varnishing

| Satisfactory | ||||||||||||

| Good results |

Strength Properties

| Shearing strength (parallel to grain) = low | ||||||||||||

| Max. crushing strength = medium | ||||||||||||

| Bending strength (MOR) = medium | ||||||||||||

| Modulus of Elasticity (stiffness) = medium | ||||||||||||

| Density (dry weight) = 31-37 lbs/cu. ft. | ||||||||||||

| Hardness (side grain) = soft | ||||||||||||

| Shrinkage, Radial = small | ||||||||||||

| Shrinkage, Tangential = small | ||||||||||||

| Modulus of Elasticity (stiffness) = low | ||||||||||||

| Density (dry weight) = 38-45 lbs/cu. ft. | ||||||||||||

| Shrinkage, Tangential = moderate | ||||||||||||

| Bending strength (MOR) = low | ||||||||||||

| Shrinkage, Tangential = very small | ||||||||||||

| Shrinkage, Tangential = fairly large | ||||||||||||

| Shrinkage, Radial = very small | ||||||||||||

| Shrinkage, Radial = moderate | ||||||||||||

| Density (dry weight) = 23-30 lbs/cu. ft. | ||||||||||||

| Compression strength (parallel to grain) = high |

The bending strength of air-dried wood of the species is similar to that of Teak, which is considered to be strong. Strength in compression parallel to grain is in the high range. Other species in this range include Teak, White oak, and Hard maple. The weight is high. The density is high.

Numerical Data

| Item | Green | Dry | English |

| Bending Strength | 8875 | 13605 | psi |

| Density | 37 | lbs/ft3 | |

| Hardness | 995 | lbs | |

| Maximum Crushing Strength | 4209 | 7215 | psi |

| Shearing Strength | 1574 | psi | |

| Stiffness | 1440 | 1716 | 1000 psi |

| Specific Gravity | 0.48 | ||

| Weight | 36 | 26 | lbs/ft3 |

| Radial Shrinkage | 3 | % | |

| Tangential Shrinkage | 6 | % | |

| Item | Green | Dry | Metric |

| Bending Strength | 623 | 956 | kg/cm2 |

| Density | 592 | kg/m3 | |

| Hardness | 451 | kg | |

| Maximum Crushing Strength | 295 | 507 | kg/cm2 |

| Shearing Strength | 110 | kg/cm2 | |

| Stiffness | 101 | 120 | 1000 kg/cm2 |

| Specific Gravity | 0.48 | ||

| Weight | 576 | 416 | kg/m3 |

| Radial Shrinkage | 3 | % |

References

Bolza, E.,1981,The Mechanical properties of 33 Solomon Islands timbers,C.S.I.R.O. Div. Building Research. Technical Paper (2nd series) No.37

Brown, W.H.,1978,Timbers of the World, No. 8 Australasia,TRADA, Red Booklet Series

Budgen, B.,1981,Shrinkage and density of some Australian and South-East Asian Timbers,C.S.I.R.O. Div. building Res. Tech Paper(2nd Series) No.38

Chudnoff, M.,1984,Tropical Timbers of the World,U.S.A. Department of Agriculture, Forest Service, Forest Products,Laboratory, Madison.

EcoTimber International, San Francisco, California. Personal Communication, 1993.

Keating, W.G., Bolza, E.,1982,Characteristics properties and uses of timbers. South East Asia, Northern,Australia and the Pacific,C.S.I.R.O. Div. Chemical Technology,Inkata Press,1

Pleydell, G.J.,1970,Timbers of the British Solomon Islands,United Africa Company (Timber) Ltd, London

Solomon Islands Forestry Department,1970,Solomon Islands Timbers Calophyllum kajewskii,Solomon Islands Timbers Timber Leaflet No.1, Solomon Islands Forestry,Department, Honiara

Solomon Islands,1976,Solomon Islands Timbers – Major Species,For Div. Min. Nat. Resources, Honiara, Timber Booklet 1

The Ecological Trading Company Limited (ETC, Newcastle upon Tyre, United Kingdom