Scientific Name

Burkea africana

Trade Name

Burkea

Family Name

Leguminosae

Common Names

Aradibo, Atakpla, Avadibo, Bak’in, Bomni, Burkea, Bwamiri, Bwanzalenga, Cabilangan, Dagbongum, Esseresu opirimu, Gbagbongum, K’iryar dutse, Kapanga, Karya gatari, Kinkili, Kinkiri, Kirintanga, Kokobi, Kolo, Kombo, Kur’di, Kuru, Langengu, M’carati, Maccarati, Mak’arfo, Makarati, Make, Malawi, Mgando, Mkarati, Monoodo, Msangala, Mucarala, Mucarati, Mukalati, Mukarati, Musheshe, Mutundungu, Namijin k’irya, Pinimo, Pirimo, Pirimu, Sandering, Siri, Tachale, Tschesili, Tschingli, Umnondo, Wild seringa, Wilde sering, Wildesering

Regions of Distribution

Africa

Countries of Distribution [VIEW MAP]

Angola, Botswana, Cameroon, Congo, Gabon, Ghana, Ivory Coast, Malawi, Mozambique, Namibia, Nigeria, South Africa, Sudan, Swaziland, Tanzania, Togo, Zaire, Zambia, Zimbabwe

Common Uses

Agricultural implements, Bedroom suites, Boat building (general), Boxes and crates, Building construction, Building materials, Cabin construction, Cabinetmaking, Charcoal, Construction, Crossties, Domestic flooring, Drawer sides, Excelsior, Factory construction, Flooring, Flooring: commercial heavy traffic, Fuelwood, Furniture , Furniture, Heavy construction, Joinery, Kitchen cabinets, Light construction, Living-room suites, Millwork, Mine timbers, Office furniture, Parquet flooring, Poles, Posts, Radio – stereo – TV cabinets, Railroad ties, Tool handles, Turnery, Vats, Vehicle parts

Environmental Profile

| Very little threat to its natural environment. | ||||||||||||

| Status unknown in many of its growth areas | ||||||||||||

| Generally secure within its natural habitat | ||||||||||||

| Data source is World Conservation Monitoring Center |

Distribution Overview

Widely distributed in dry savanna forests from Nigeria southward to Transvaal.

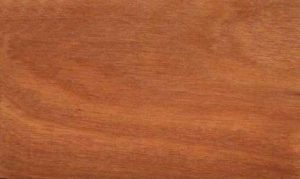

Heartwood Color

| Brown | ||||||||||||

| Yellow to golden-yellow to orange | ||||||||||||

| Reddish brown | ||||||||||||

| Dark brown | ||||||||||||

| Dark brown | ||||||||||||

| Turn reddish brown upon exposure | ||||||||||||

| Greyish brown |

Sapwood Color

| Pinkish | ||||||||||||

| White to yellow | ||||||||||||

| Color not distinct from heartwood |

Grain

| Interlocked | ||||||||||||

| Figure | ||||||||||||

| Distinct (figure) | ||||||||||||

| Closed | ||||||||||||

| Wavy | ||||||||||||

| Stripe (figure) |

| Interlocked | ||||||||||||

| Distinct and fine figure | ||||||||||||

| Distinct figure | ||||||||||||

| Wavy | ||||||||||||

| Striped figure |

Texture

| Medium | ||||||||||||

| Fine | ||||||||||||

| Fine to medium | ||||||||||||

| Coarse |

Luster

| Lustrous |

Natural Growth Defects

| Center is often decayed |

Natural Durability

| Very durable | ||||||||||||

| Durable | ||||||||||||

| Resistant to attack from termites (Isoptera) | ||||||||||||

| Susceptible to attack from termites (Isoptera) | ||||||||||||

| Untreated wood in contact with ground is very resistant to decay | ||||||||||||

| Susceptible to attack from powder post (Lyctid & Bostrychid) beetles | ||||||||||||

| Resistant to termite attack | ||||||||||||

| Resistant to attack from powder post (Lyctid & Bostrychid) beetles | ||||||||||||

| Pinworms (ambrosia beetles) are commonly present | ||||||||||||

| Perishable | ||||||||||||

| Moderately resistant to termite (Isoptera) attack | ||||||||||||

| Moderately resistant to marine borer attack |

Odor

| No specific smell or taste |

Light-Induced Color Change

| Darker |

Kiln Schedules

| Kiln Drying Rate (in days) is rather slow | ||||||||||||

| UK=B US=T2C2/T2C1 Fr=2 | ||||||||||||

| UK=C US=T3C2/T3C1 Fr=3 | ||||||||||||

| T2 – C2 (4/4) Us Schedule B (4/4) United Kingdom | ||||||||||||

| Dry at a moderate speed |

Drying Defects

| Checking | ||||||||||||

| Slight end splitting | ||||||||||||

| Slight problem with splitting and distortion |

Ease of Drying

| Easy | ||||||||||||

| Variable results. | ||||||||||||

| Shrinkage Green to12% MC | ||||||||||||

| Radial and tangential shrinkage from 1-2% | ||||||||||||

| Dries slowly with moderate ease |

Kiln Drying Rate

| Very slow (>28 days for boards < 32 mm, to >84 days for boards >= 63 mm) |

Tree Size

| Trunk diameter is 100-150 cm | ||||||||||||

| Tree height is 30-40 m | ||||||||||||

| Tree height is 20-30 m | ||||||||||||

| Trunk diameter is 200-250 cm |

Comments

General finishing qualities are rated as good

Cutting Resistance

| Cutting Resistance with dry wood is easy | ||||||||||||

| Easy to saw |

Gluing

| Easy to glue | ||||||||||||

| Glues well |

Moulding

| Poor moulding results |

Movement in Service

| Small | ||||||||||||

| Holds shape after seasoning | ||||||||||||

| Good stability after seasoning |

Nailing

| Difficult to nail | ||||||||||||

| Pre-boring is recommended to avoid splitting | ||||||||||||

| Possible if prebored |

Planing

| Difficult to plane | ||||||||||||

| Planes to a poor finish | ||||||||||||

| Torn grain is common |

Resistance to Impregnation

| Heartwood is extremely resistant | ||||||||||||

| Sapwood is permeable | ||||||||||||

| Heartwood is resistant |

Resistance to Splitting

| Poor |

Response to Hand Tools

| Easy to Work | ||||||||||||

| Difficult to machine | ||||||||||||

| Moderate working qualities | ||||||||||||

| Easy to machine |

Sanding

| Good sanding finish |

Screwing

| Pre-boring suggested to avoid splitting |

Turning

| Good results | ||||||||||||

| Easy to turn |

Polishing

| Satisfactory results | ||||||||||||

| Good results |

Staining

| Staining properties are good |

Strength Properties

| Shrinkage, Tangential = very small | ||||||||||||

| Shrinkage, Radial = very small | ||||||||||||

| Shearing strength (parallel to grain) = medium | ||||||||||||

| Max. crushing strength = medium | ||||||||||||

| Density (dry weight) = 46-52 lbs/cu. ft. | ||||||||||||

| Bending strength (MOR) = medium | ||||||||||||

| Shrinkage, Radial = small | ||||||||||||

| Max. crushing strength = high | ||||||||||||

| Density (dry weight) = 61-67 lbs/cu.ft. | ||||||||||||

| Shrinkage, Tangential = moderate | ||||||||||||

| Modulus of Elasticity (stiffness) = very low | ||||||||||||

| Hardness (side grain) = medium | ||||||||||||

| Dnesity (dry wieght) = 53-60 lbs/cu. ft. | ||||||||||||

| Bending strength (MOR) = low | ||||||||||||

| Bending strength (MOR) = high | ||||||||||||

| Very heavy | ||||||||||||

| Toughness-Hammer drop (impact Strength) = high | ||||||||||||

| Shrinkage, Volumetric = very small | ||||||||||||

| Shrinkage, Volumetric = small | ||||||||||||

| Shrinkage, Volumetric = moderate | ||||||||||||

| Shrinkage, Tangential = small | ||||||||||||

| Shearing strength (parallel to grain) = very high | ||||||||||||

| Shearing strength (parallel to grain) = high | ||||||||||||

| Modulus of Elasticity (stiffness) = medium | ||||||||||||

| Modulus of Elasticity (stiffness) = low | ||||||||||||

| Hardness (side grain) = very hard | ||||||||||||

| Hardness (side grain) = soft | ||||||||||||

| Density = high | ||||||||||||

| Density (dry weight) = 67-75 lbs/cu. ft. | ||||||||||||

| Bending strength (MOR) = very high |

Numerical Data

| Item | Green | Dry | English |

| Bending Strength | 10836 | 16513 | psi |

| Density | 53 | lbs/ft3 | |

| Hardness | 1813 | lbs | |

| Impact Strength | 54 | inches | |

| Maximum Crushing Strength | 5408 | 8171 | psi |

| Shearing Strength | 2475 | psi | |

| Stiffness | 1264 | 1472 | 1000 psi |

| Specific Gravity | 0.64 | ||

| Weight | 52 | 44 | lbs/ft3 |

| Radial Shrinkage | 2 | % | |

| Tangential Shrinkage | 5 | % | |

| Volumetric Shrinkage | 8 | % | |

| Item | Green | Dry | Metric |

| Bending Strength | 761 | 1161 | kg/cm2 |

| Density | 849 | kg/m3 | |

| Hardness | 822 | kg | |

| Impact Strength | 137 | cm | |

| Maximum Crushing Strength | 380 | 574 | kg/cm2 |

| Shearing Strength | 174 | kg/cm2 | |

| Stiffness | 88 | 103 | 1000 kg/cm2 |

| Specific Gravity | 0.64 | ||

| Weight | 833 | 705 | kg/m3 |

| Radial Shrinkage | 2 | % | |

| Tangential Shrinkage | 5 | % |

References

Babajide, Lucas E., Shegun, Ajayi D.,1966,Stiffness and specific gravity related to other mechanical properties for,seven tropical timbers.,Nigeria Federal Department Forest Research, Ibadan, Report No.10

Banks, C.H. and J.P. Schoeman. 1963. Railway Sleeper and Crossing Timbers. Bulletin No. 41, Republic of South Africa. The Government Printer, Pretoria, South Africa.

Banks, C.H., Kromhout, C.P.,1966,Notes on the Timber of Burkea africana Hook with Particular Reference to,Material from S.W.Africa,Bosbou in Suid-Afrika,No.7, pp17-29

Banks, C.H., Schoeman, J.P., Otto, K.P.,1977,The Mechanical Properties of Timbers with particular reference to South,Africa,South African Forestry Research Institute Bulletin,(Ed.,Schoeman, J.P. 1973 & Otto K.P. 1976,No.48

Bolza, E., Keating, W.G.,1972,African Timbers – the Properties, Uses and Characteristics of 700 Species,C.S.I.R.O. Div. of Building Research

Bryce, J.M.,1967,Commercial Timbers of Tanzania,Tanzanian Forestry Division Util. Sec. Moshi

Chudnoff, M.,1984,Tropical Timbers of the World,U.S.A. Department of Agriculture, Forest Service, Forest Products,Laboratory, Madison.

Dalziel, J.M.,1937,The Useful Plants of West Tropical Africa,Crown Agents for the Colonies

Eggeling, W.J.,1940,Indigenous Trees of Uganda,Govt. Printer Entebbe Uganda

Erfurth, T., Rusche, H.,1976,The Marketing of Tropical Wood A. Wood Species from African Moist Forests,F.A.O. Forestry Department

Fanshawe, D.B.,1962,Fifty Common Trees of Northern Rhodesia,Natural Resources Board and Forestry Department, Ndola

Farmer, R.H.,1972,Handbook of Hardwoods,HMSO

Ferreirinha, M.P.,1955,Catalogo des Madeiras de Mocambique (pt 1,Min. do Ultramar Junta Invest. do Ultranar Memorias Serie Botanica, 2

Fortin, Y., Poliquin, J.,1976,Natural Durability and Preservation of 100 Tropical African Woods,International Development Research Centre, Canada

HMSO. 1981. Handbook of Hardwoods, 2nd Edition. Revised by R.H. Farmer. Department of the Environment, Building Research Establishment, Princes Risborough Laboratory, Princes Risborough, Aylesbury, Buckinghamshire.

Irvine, F.R.,1961,Woody Plants of Ghana,O.U.P. London

Jay, B.A.,1968,Timbers of West Africa,TRADA, Red Booklet Series

Keay, R.W.J. 1989. Trees of Nigeria. Revised Version of Nigerian Trees. Clarendon Press, Oxford.

Murira, K.,1984,Natural Durability Tests of Tanzanian Timbers 1955 – 1982,Tanzania Forestry Research Institute, Timber Utilisation Research Centre,,Moshi.

Organisation for European Economic Co-operation,1951,African Tropical Timber (Nomenclature, Description,OEEC

Pardy, A.A.,1952,Notes on Indigenous Trees and Shrubs of S. Rhodesia – Burkea africana,(Hook,Ministry of Agriculture and Lands S. Rhodesia Bulletin No.1651

Scott, J.D.,1950,Some Nigerian Timbers,Nigerian Forestry Department

Scott, M.H.,1935,Weights of South African Growth Timbers,South African Department of Agriculture and Forestry Bulletin,No.145,Forest Products Institute, Forestry Series No.1

Scott, M.H.,1950,Notes on the more Important African Timbers Imported into the Union with,Special Ref. to Port. E.A. Species,Journal of the South African Forestry Association,No.19,pp18-62,[South,African Forestry Journal]

Scott, M.H.,1953,Utilisation Notes on South African Timbers,South African Forestry Department Bulletin No.36

Storrs, A.E.G.,1979,Know your Trees – Some of the Common Trees found in Zambia,Zambia Forestry Department, Ndola

Takahashi, A.,1978,Compilation of Data on the Mechanical Properties of Foreign Woods (Part,III) Africa,Shimane University, Japan, Research Report on Foreign Wood No. 7

Tanzania Forest Department,1960,The Natural Durability of Local Timbers,Tanzanian Forest Dept. Tech. Note,No.14

Tanzania Forest Department,1961,Timbers of Tanganyika – Brachystegia spiciformis,Tanzania Forest Dept. Util. Sec. Moshi – Timbers of Tanganyika

Tanzania Forest Division,1966,Kiln Drying Schedules for Tanzania Timbers Technical Note no.38,Tanzania Forest Div. Util. Sec. Moshi

Tanzania Forest Division,1967,Timbers of Tanganyika – Burkea africana,Tanzania Forest Div. Util. Sec. Moshi – Timbers of Tanganyika

WCMC. 1992. Conservation Status Listing – Trees and Timbers of the World. World Conservation Monitoring Center-Plants Programme, Cambridge, CB3 ODL, United Kingdom.

White, F.,1962,Forest Flora of Northern Rhodesia,O.U.P. London